Dirt Screens for Sale: Your Comprehensive Guide to Choosing the Right Equipment

Wiki Article

Achieve Superior Material Separation With Advanced Dirt Screens for Recycling Plants

In the ever-evolving world of recycling plants, achieving superior product separation is important to making best use of effectiveness and success. Enter innovative dirt screens, a technology that holds the assurance of reinventing the way waste is refined. These advanced screens are made to effectively different dirt and various other pollutants from recyclable materials, making certain a higher top quality outcome. Yet exactly how do they function? And what are the essential advantages of integrating these displays into reusing plant procedures? In this discussion, we will certainly explore the solution to these questions and explore the aspects to consider when selecting dust screens, in addition to their execution and maintenance. Prepare to discover the keys behind accomplishing premium material separation and remain tuned for the valuable insights that lie in advance.The Significance of Advanced Dirt Screens

The value of advanced dirt displays in reusing plants can not be overemphasized as they play a critical function in separating and removing pollutants from recyclable products. These displays are especially made to efficiently and effectively remove dirt, debris, and other unwanted materials from the recycling process, ensuring that top quality and only clean recyclables are refined better.Among the main factors why sophisticated dirt screens are essential is that they aid boost the total high quality of recyclable materials. By removing contaminants such as dust, rocks, and various other non-recyclable products, the screens make certain that the last recycled products are of higher pureness and satisfy the required industry criteria. This not just boosts the value of the recycled materials however additionally boosts their marketability.

Additionally, advanced dust screens aid to avoid damages to reusing equipment. Impurities like rocks or steel objects can create considerable damage to equipment such as shredders, conveyors, and crushers, leading to expensive repair work and downtime. By properly separating these impurities at the onset of the recycling procedure, dirt displays help to lengthen the lifespan of the tools and decrease upkeep expenses.

Along with improving worldly quality and securing equipment, advanced dust screens likewise add to a much safer working setting - dirt screens for sale. By eliminating sharp things, hazardous products, or possibly hazardous materials, these displays decrease the danger of accidents or injuries to employees, ensuring a much safer office for everyone included

Exactly How Advanced Dust Screens Work

Advanced dirt screens in reusing plants feature by utilizing specific systems to different and eliminate contaminants from recyclable materials, making sure that high-grade and only tidy materials continue with the recycling procedure. These displays are designed to handle huge quantities of mixed waste and efficiently get rid of undesirable substances, such as dirt, particles, and smaller sized particles, from the recyclable materials.The primary step while doing so includes the feeding of blended waste materials onto the dirt screen. The screen is geared up with a series of openings or perforations that allow smaller particles to go through while keeping larger and better materials. As the waste materials relocate along the display, a mix of mechanical resonances and gravitational forces aids to divide the pollutants from the recyclables.

To maximize efficiency, progressed dust displays employ various technologies, such as oscillating or shaking displays, to improve the separation process (dirt screens for sale). These displays can be fine-tuned to accomplish the desired separation dimension, making sure that only the cleanest and most important products proceed with the recycling procedure

Furthermore, some advanced dust displays utilize air jets or suction systems to further boost the separation process. These systems impact or vacuum cleaner away lighter impurities, such as paper or plastic movie, leaving behind the larger and better recyclable materials.

Trick Benefits of Making Use Of Advanced Dirt Screens

Using innovative dirt displays in recycling plants uses countless benefits in regards to performance, effectiveness, and general quality of the reusing process. These innovative screens are designed to divide dirt, debris, and various other unwanted products from the recyclable materials, leading to a purer final product. One crucial benefit of utilizing advanced dirt displays is improved effectiveness. By effectively eliminating dust and debris, the displays allow for a much more structured recycling process, reducing the time and labor needed for hand-operated sorting. This results in raised productivity and throughput in recycling plants.

Another advantage is the improved efficiency of the reusing procedure. Advanced dust displays are designed to accurately and effectively separate recyclable materials from pollutants, view publisher site making certain a better Find Out More final result. This aids to meet strict recycling standards and permits the production of cleaner and purer materials that can be utilized in different markets.

Along with effectiveness and performance, making use of innovative dust displays likewise adds to the total quality of the recycling process. By removing dirt and particles, the displays aid to decrease the threat of contamination, making certain that the recycled products are of a greater requirement. This not just enhances the value and marketability of the recycled products yet additionally advertises sustainability by minimizing the requirement for virgin resources.

Factors to Think About When Picking Dirt Screens

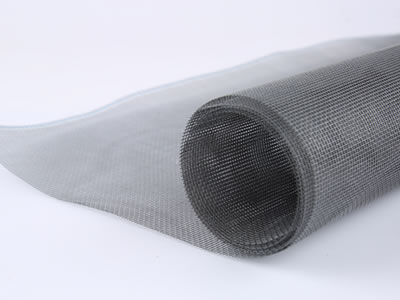

When choosing dust screens for recycling plants, it is essential to think about numerous elements to make sure optimum performance and effectiveness. Among the first elements to take into consideration is the dimension of the screen. The size of the dirt display will certainly determine the size of the bits that can travel through, so it is crucial to select a display dimension that is ideal for the specific materials being processed.One more crucial variable to consider is the material of the screen. Different materials have different levels of toughness and resistance to put on and tear. It is vital to choose a screen material that can endure the extreme problems of the recycling plant and keep its performance with time.

In addition, the layout and arrangement of the dust display need to be taken into consideration. The display needs to be made to maximize the separation of various products and protect against obstructing or clogs. The spacing in between the cables or perforations on the screen need to be thoroughly chosen to accomplish the desired separation efficiency.

Furthermore, the maintenance demands of the dirt screen should additionally be taken into consideration. Displays that are simple to clean and keep will help to reduce downtime and guarantee continuous operation of the recycling plant.

Execution and Upkeep of Dirt Screens

To efficiently implement and keep dust displays in recycling plants, mindful factor to consider get redirected here should be offered to their installment and continuous upkeep. Correct installation is essential to make certain the displays function ideally and offer superior product separation. Throughout installation, it is very important to place the displays in such a way that enables simple access for upkeep and cleaning. This might involve calculated placement of gain access to points and using suitable assistance structures.Regular upkeep is important to keep dust screens in optimum condition and maximize their effectiveness - dirt screens for sale. It is advised to establish a maintenance routine and stick to it strictly. This includes routine examinations to identify any indications of wear or damages, such as rips or openings in the screens. Any problems must be without delay addressed to stop additional degeneration and keep reliable material separation.

Cleaning up the displays consistently is also important to prevent blockages and ensure continuous procedure. This can be done making use of numerous approaches such as air or water blasts, depending upon the kind of screen and the level of dust build-up. It is crucial to adhere to maker guidelines and recommendations when cleaning the displays to prevent triggering any damages.

Conclusion

Finally, making use of advanced dirt screens in recycling plants is important for accomplishing premium product splitting up. These displays effectively remove dust and various other contaminants, making certain the manufacturing of top quality recycled materials. The essential benefits of using sophisticated dirt screens include increased efficiency, improved item top quality, and lowered upkeep expenses. When selecting dirt screens, factors such as display dimension and product ought to be thought about. Proper implementation and normal upkeep of these screens are vital for optimal performance.

These sophisticated screens are made to separate dust, particles, and other undesirable materials from the recyclable products, resulting in a purer end item. Advanced dirt displays are developed to accurately and successfully separate recyclable products from pollutants, ensuring a greater quality end item. The size of the dust screen will certainly identify the dimension of the bits that can pass through, so it is crucial to select a screen dimension that is appropriate for the certain materials being refined.

In conclusion, the usage of innovative dirt displays in recycling plants is vital for achieving premium material splitting up. When choosing dirt displays, factors such as display dimension and material must be considered.

Report this wiki page